Alands PMMA Acrylic Glitter glitter plastic sheet with factory price

Brand : ALANDS

Product origin : Jinan,China

Delivery time : 10-15 days

Supply capacity : 500 Ton/Tons per Month

Alands PMMA Acrylic Glitter glitter plastic sheet with factory price

—— Alands Glitter Acrylic/PMMA Sheets ——

♦ Alands Glitter Acrylic/PMMA Sheet ♦

Density | 1.2g/cm3 |

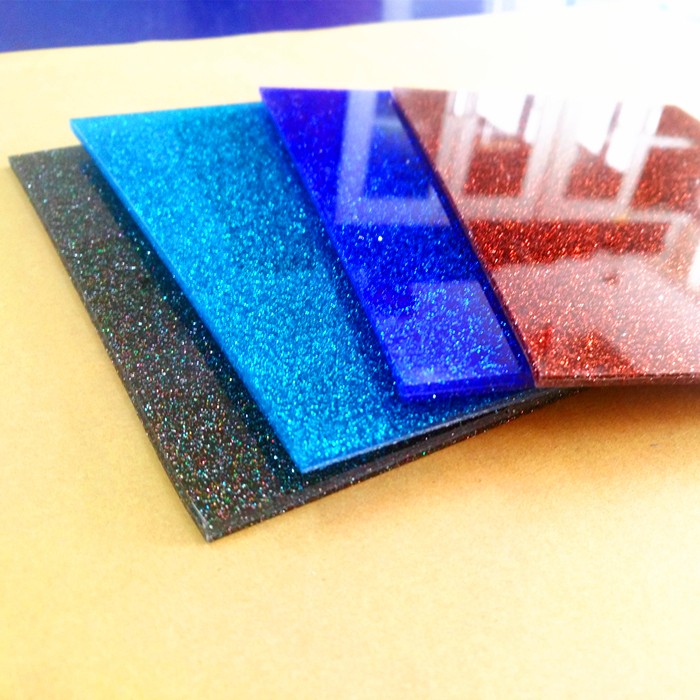

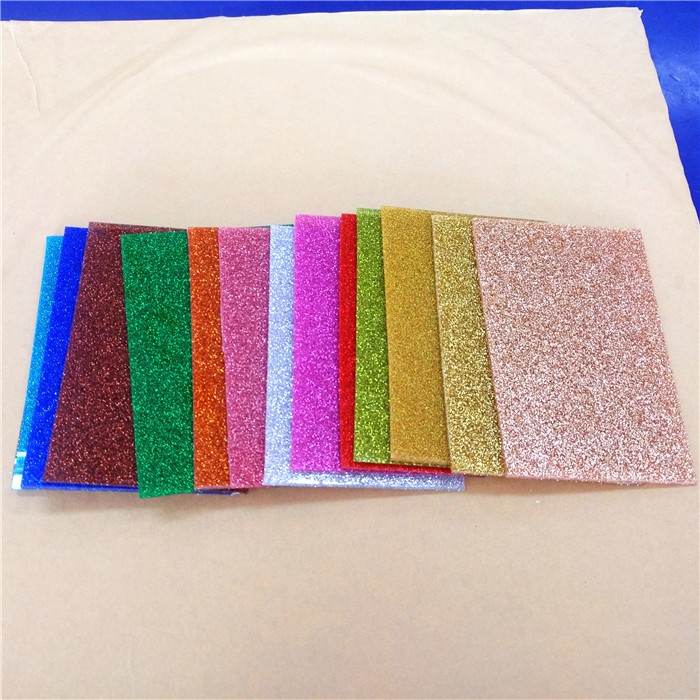

Color | Gold, sliver,red, blue, white, black, etc... more than 100 kinds of colors. |

| Size/mm | 1250*2500/1880*1260/1240*2005/1560*620/1560*980 |

Material | Adopt the pure LUCITE, high quality MMA raw material. |

Technology | Cast/Extruded acrylic sheet production process |

Equipment | Imported glass models (from Pilkington Glass in U. K. ) |

Quality | Acrylic sheet conforms to the environmental protection standard, already through SGS environmental protection authentication. |

payment | L/C, T/T, Western Union, Paypal |

MOQ | 34 PCS |

Delivery | 3-15 working days after confirm your order |

♦ Alands Acrylic Sheet Technical Properties ♦

Specific Gravity | 1.19-1.20 |

Rockwell Hardness | M-100 |

Shear Strength | 630Kg/cm2 |

Tensile Strength | 760Kg/cm2 |

Yield Strength | 1260Kg/cm2 |

Rupture Strength | 1050Kg/cm2 |

Light Transmittance (Clear sheet) | 93% |

Refractive Index | 1.49 |

| Heat Distortion Temperature | 100℃ |

| Thermal Forming Temperature | 140℃-180℃ |

Coefficient of linear Thermal Expansion | 6×10-5cm/cm/℃ |

| Dielectric Strength | 20Kv/mm |

| Water(24HRS)Absorption | 0.30% |

Note: We can make product sizes according to your requirements & QTY

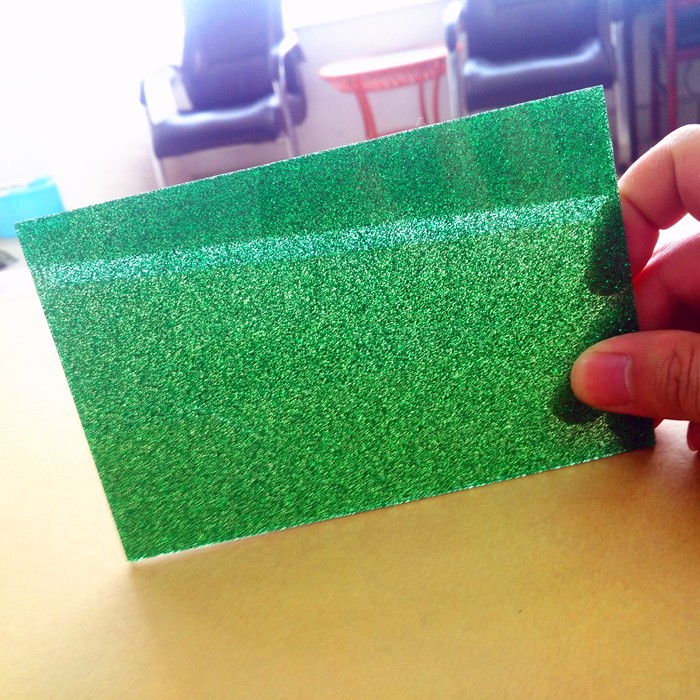

♦ Alands Glitter Acrylic Sheet Description ♦

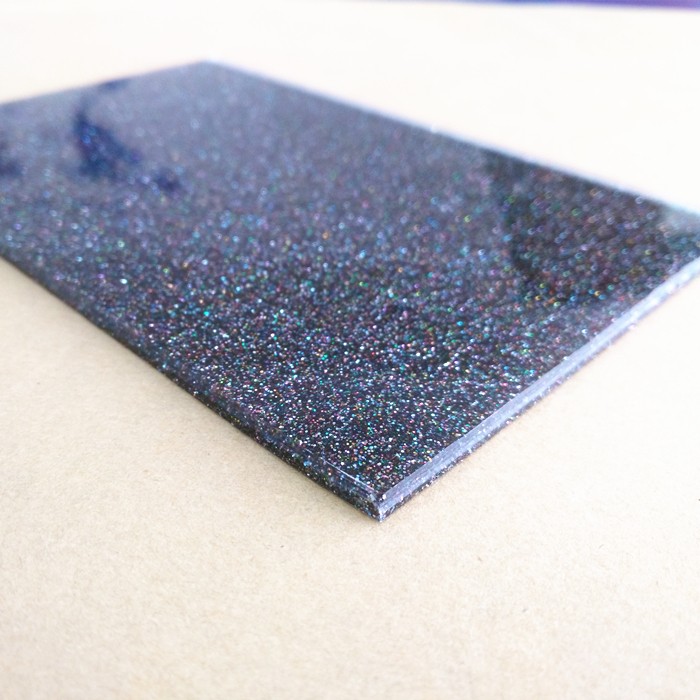

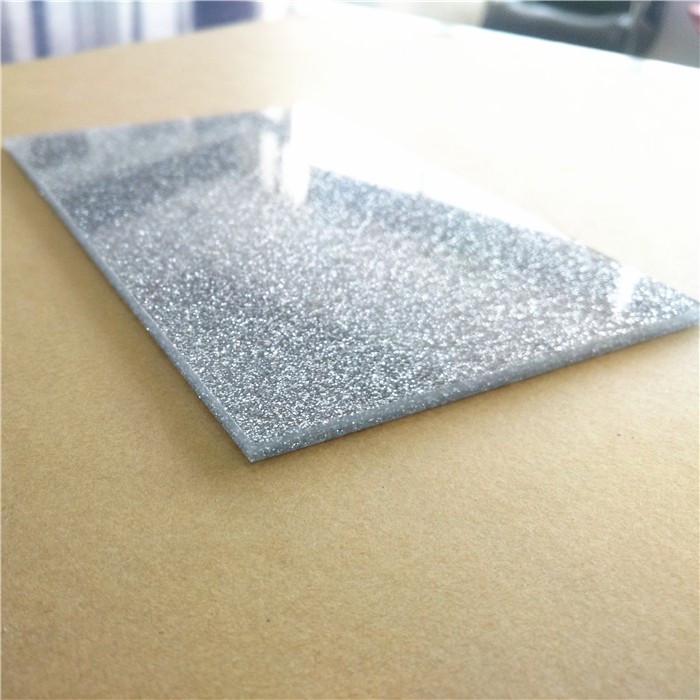

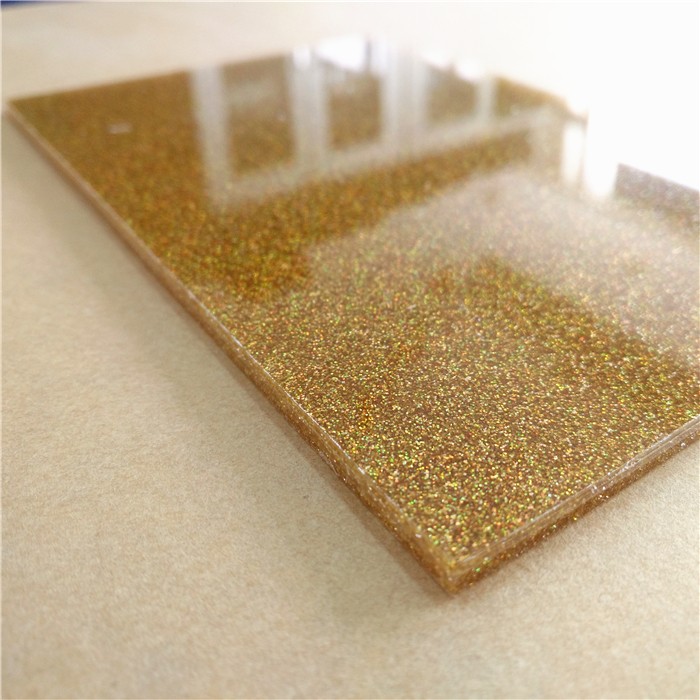

A wide range of decorative acrylic sheet which is hand-mixed and cast to give a striking effect. The glitter particles

deflect the light creating a sparkling 3D effect.

Due to the sheets being hand-mixed the product colour shade may slightly vary with each manufacturing batch.

♦ Our Service ♦

• Drilling • Polishing • Thermoforming • Fabrication • CNC or Laser machining • cut to size

♦ Hot Colors ♦

♦ Advantages of Glitter Acrylic Sheet ♦

1. Excellent Weather Resistance √

High adaptability to natural environment, even for a long time in the sunlight, wind blowing & rain will not change the performance,

anti-aging performance is good, you can also feel at easy to use in the outdoor.

2. Good Processing Performance √

Both suitable for mechanical processing and heat forming.

3. Excellent Comprehensive Performance √

Acrylic has wide varieties ,rich colors, has extremely excellent comprehensive performance, provides a variety choices for designers,

acrylic can be dyed/surface can be painted/silk screen/vacuum coating.

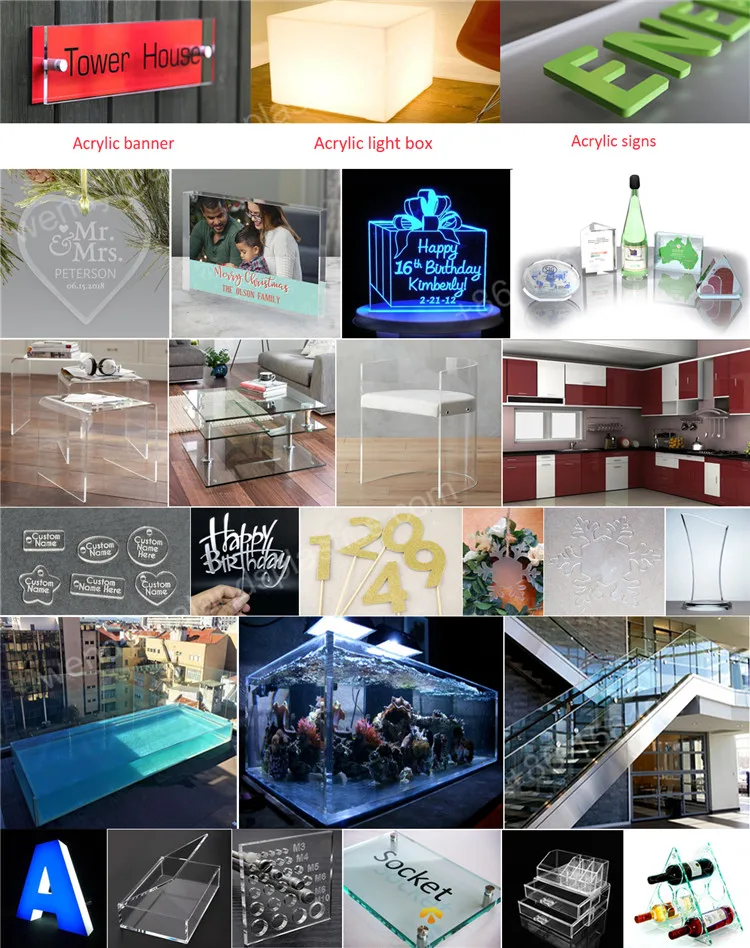

1) Unusual decorations, corridors and pavilions in gardens and recreational and rest places

2) Interior & exterior decorations of commercial buildings, and curtain walls of the modern urban buildings

3) The transparent containers,front wind shields of motorcycles/airplanes/trains/ships/vehicles/motor boats,

sub marines

4) Telephone booths, street name plates and sign boards

5) Instrument and war industries - windscreens, army shields

6) Walls, roofs, windows, screens and other high quality indoor decoration materials

7) Sound insulation shields on express ways/city overhead highways

8) Agriculture greenhouses and sheds.

1.What's the difference between cast and extruded acrylic?

Acrylic is produced in two basic ways, cast and extruded. Cast acrylic is produced by mixing acrylic liquid ingredients in mould. A chemical process in mould creates a homogeneous material with equivalent properties in all directions. In contrast, extruded is produced by continuously pushing acrylic mass through a form, while the chemical process takes place.

Laser cutting

When laser cutting extruded acrylic , there will become blurry on one side. On the cast acrylic there is not the case. The edges on extruded acrylic may look a bit different depending on the direction of the acrylic extrusion.

Laser engraving

The Laser engraving will on extruded acrylic look matte Grey. On the cast acrylic will look matte white.

Heat bending and Thermoforming

A sheet of extruded acrylic could, because of the acrylic extrusion direction, behave differently depending on the bending direction relatively to the extrusion. With cast acrylic, it makes no difference.

Scratch-resistant

Cast acrylic is more scratch resistant than extruded acrylic.

Flame polishing

Cast acrylic is harder to flame polish.

Colour

Cast acrylic is produced in many different colors and thicknesses. The colour selection is limited for extruded acrylic.

Tension

There is more tension in extruded acrylic.

2.Does acrylic discolour if left in the sun?

Most of the acrylic sheets sold by Alands are UV Stabilized otherwise stated as indoor use only (eg: acrylic mirror sheets). This means that with proper maintenance of the acrylic sheet, it should last 10 years or more before it ever yellows.

3.Is acrylic food safe?

Please be advised that clear cast acrylic sheets are in compliance with the FDA Food Additive Regulation 21CFR177.1010 ( Acrylic and Modified Acrylic Plastics, Semi-Rigid and Rigid ) for use in contact with all types of food except for high alcohol content foods (greater than 8% alcohol) at or below room temperature.