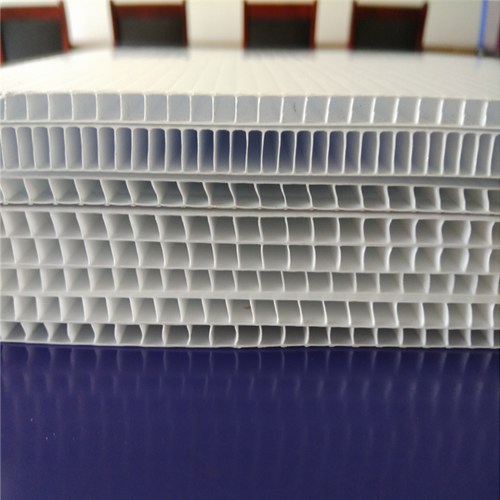

915mm x 1830mm PP Plastic Template for Construction Formwork Usage

Brand : ALANDS

Product origin : Jinan,China

Delivery time : 10-15 days

Supply capacity : 500 Ton/Tons per Month

915mm x 1830mm PP Plastic Template for Construction Formwork Usage

In China ,annual consumption of wood building construction formwork is 50 million cubic meters, and the furniture and building decoration industry consumes more than 160 million cubic meters of wood. If plastic can be used to replace wood, 4.5 million cubic meters of logs can be saved, equivalent to 54,000 forest area, can also comprehensively utilize 1 million tons of waste plastic. In 2019, the construction industry in Shandong completed an output value of more than 200 billion yuan, and the completed construction area exceeded 200 million square meters. The output value of a single formwork reached 3 to 4 billion yuan. It is expected to increase by 15% to 20% in the next few years.

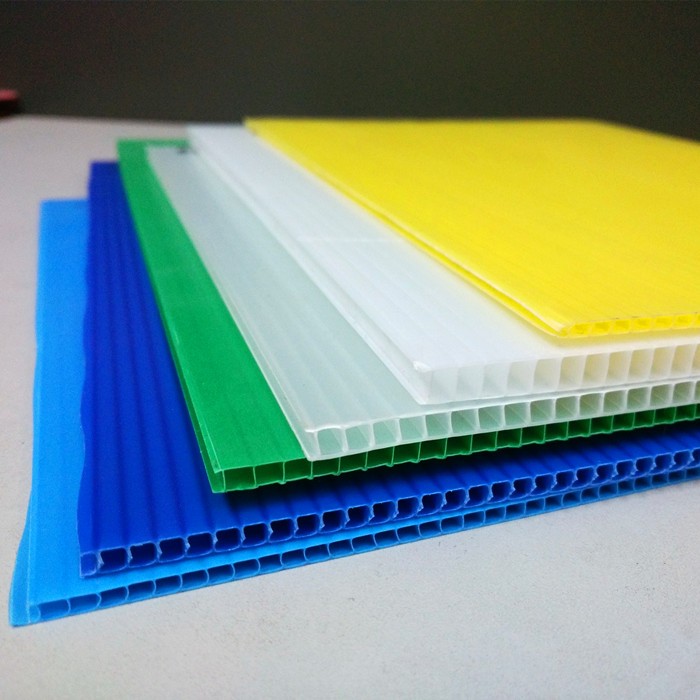

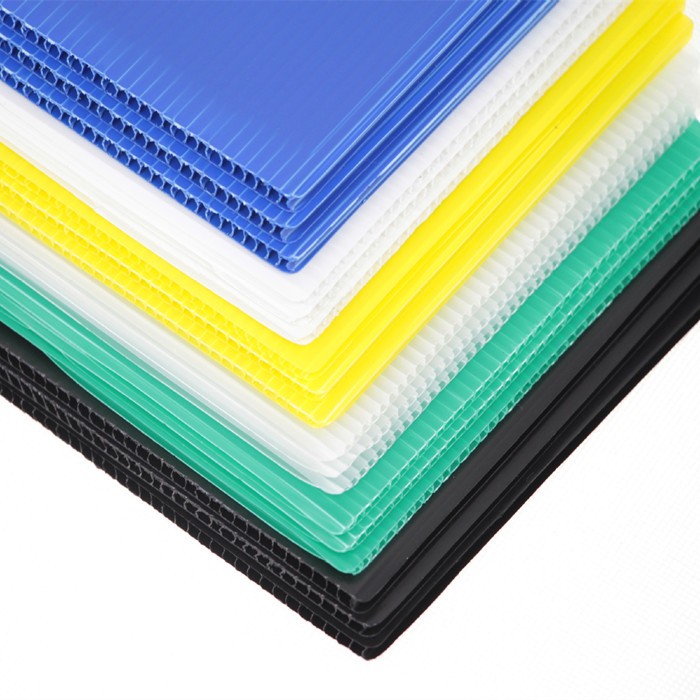

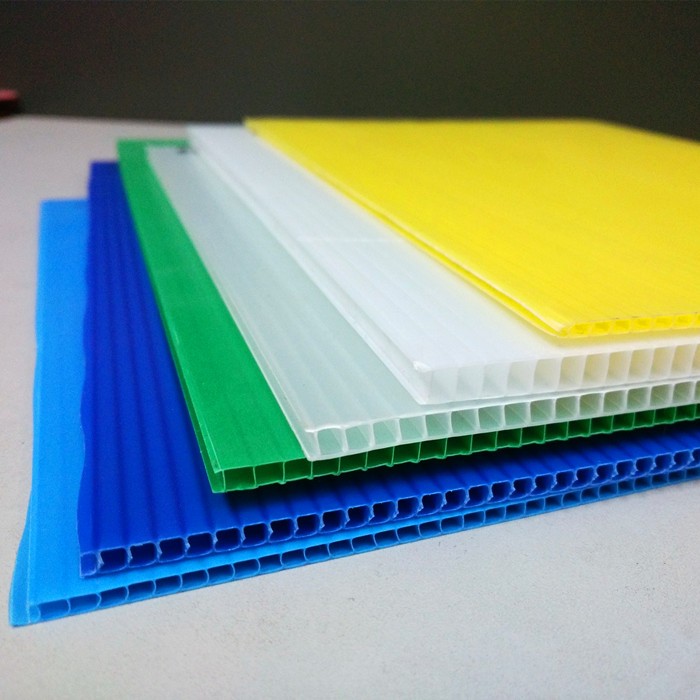

Advantage of PP Plastic Template

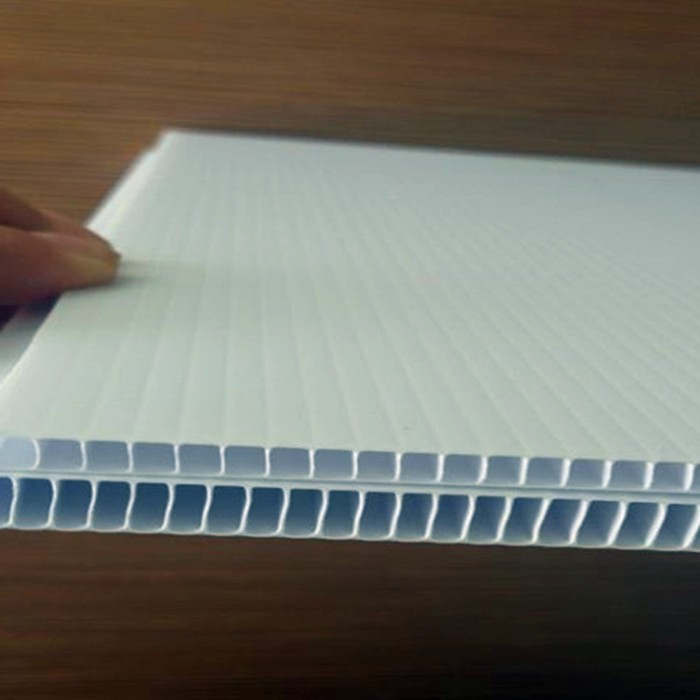

1. Light weight, high strength, good hardness, impact resistance and wear resistance;

2. The surface is smooth and smooth; the casting effect is good;

3. No moisture absorption, no deformation, no mildew; long-term immersion in water, no delamination, no foaming,stable plate size, especially suitable for use in underground and humid environments;

4. Good toughness, can be used for various special-shaped templates with varying surfaces;

5. Fire retardant, self-extinguishing in case of fire, high temperature resistance;

6. Acid and alkali resistance, corrosion resistance, non-sincerely suitable for use in coastal areas, mines, sea dams and other projects. No need to do any anti-corrosion treatment in use and storage, it will not pollute the concrete surface;

7. The turnover can be used more than 50 times, and the service life is long;

8. Waste products can be recycled and reprocessed, making full use of waste raw materials. Compared with wood formwork and bamboo plywood, the cost of waste is low, which can greatly reduce the cost of the project;

9. Environmental protection and energy saving, no pollution, no toxic and harmful gas emissions;

10. Easy demoulding, no need to brush demoulding agent, tapping on the template can fall off, shortening man-hours, saving manpower and speeding up the project progress;

11. Easy to process, can be nailed, sawed, drilled, and can be connected and combined arbitrarily.

12. Easy to remove, easy to install and remove, fast and safe. The support is easy to operate. It is beneficial to organize construction and improve work efficiency.

Comparison of Different Templates

Traditional building templates made of wooden boards and bamboo boards cannot be reused, which not only wastes wood resources, but also damages the ecological environment. Now, the use of PP plastic building templates can not only save 15% of the overall cost, but also 100% recycle and protect the environment. This is a new trend in the building template industry.

| Item | Reuse Times | Feature |

| PP Plastic Template | 50 | High hardness and strength, fire resistance, waterproof, light weight, convenient transportation, many times of turnover, low cost, easy to disassemble |

| Wood Template | 1 to 20 | Easy to absorb water and expands,reused times is less, waste forest resources |

| Bamboo Template | 5 to 20 | Easy to absorb water and expands,reused times is less, waste forest resources |

| Steel Frame Template | 20 + | High cost, inconvenient disassembly, consume labor power and the weight is heaviest |

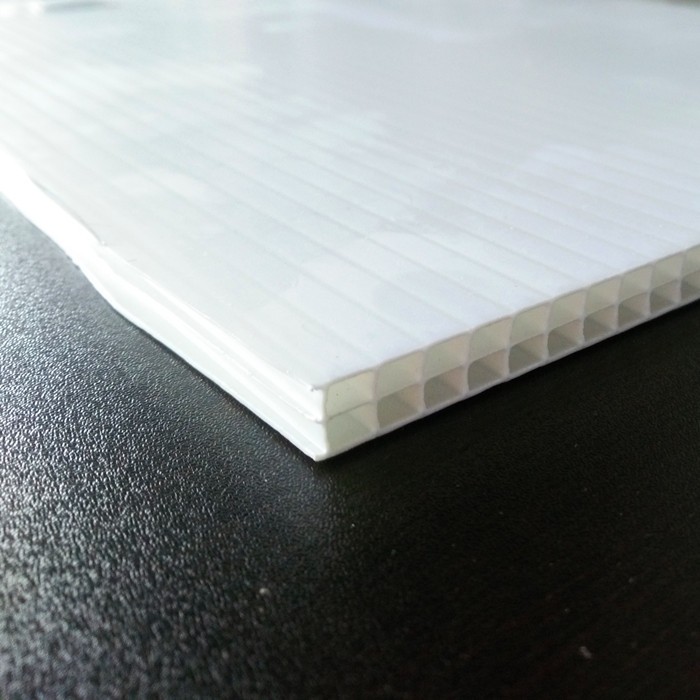

Specification of PP Plastic Template

| Size | 915mm*1830mm |

| Thickness | 15mm |

| Bending Strength (Vertical Pressure) | 29 Mpa |

| Bending Modulus (Vertical Pressure) | 1593Mpa |

| Grip Screw Force | 1280N |

| Maximum Damage Load (Vertical Pressure) | 1024N |

| Water absorption | 0.0037 |

| Static Bending Intensity Retention Rate | 0.98 |

| Shore Hardness | 75 |

| Appearance Quality | No surface crack,No bubbling |

| Vicat Softening Point | 76.6℃ |

| Apparent Density | 0.7g/cm³ |

Workshop of PP Plastic Template

Shipment of PP Plastic Template