black 5mm pvc sheets 4x8 pvc 3mm 5mm foam sheet

Brand : ALANDS

Product origin : Jinan,China

Delivery time : 10-15 days

Supply capacity : 15000 tons per year

black 5mm pvc sheets 4x8 pvc 3mm 5mm foam sheet

black 5mm pvc sheets 4x8 pvc 3mm 5mm foam sheet

Jinan Alands Plastic Co., Ltd, located in Jinan, Shandong Province, is specialized in producing PVC foam board

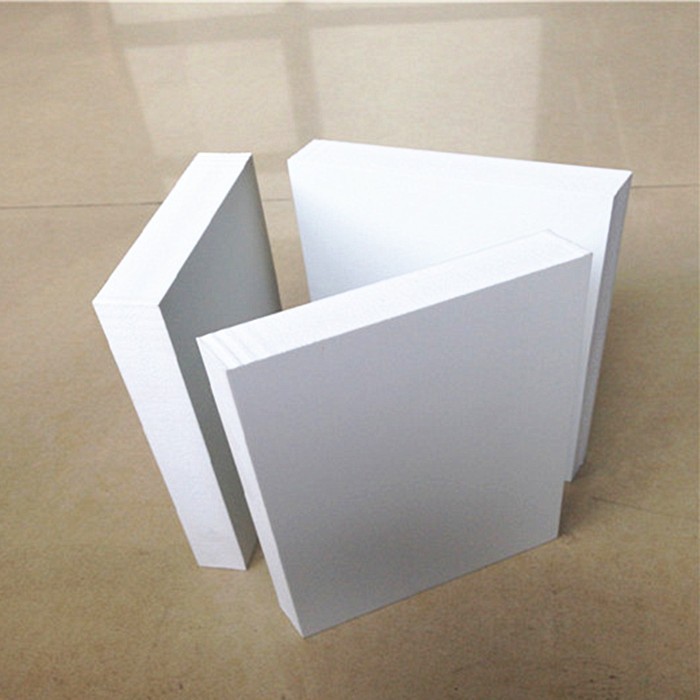

We have PVC free foam and celluka foam board, thickness range from 1mm to 30mm.

Our products are widely exported to Aisa, Middle East, Europe, South America etc. different countries and regions. Welcome to contact us!

| Name | PVC Foam Board/Sheet |

| Material | PVC resin 60%, Ca 20%, stabilizer and other polymers 6%, other 14% |

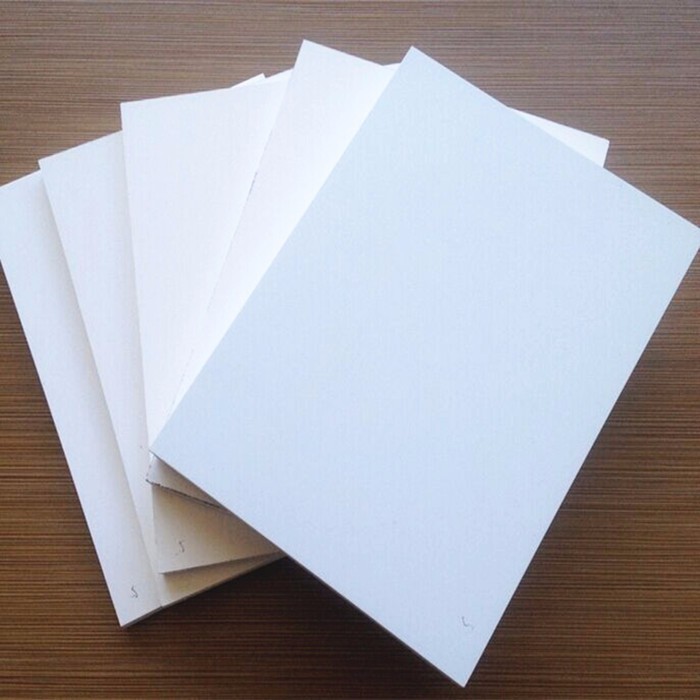

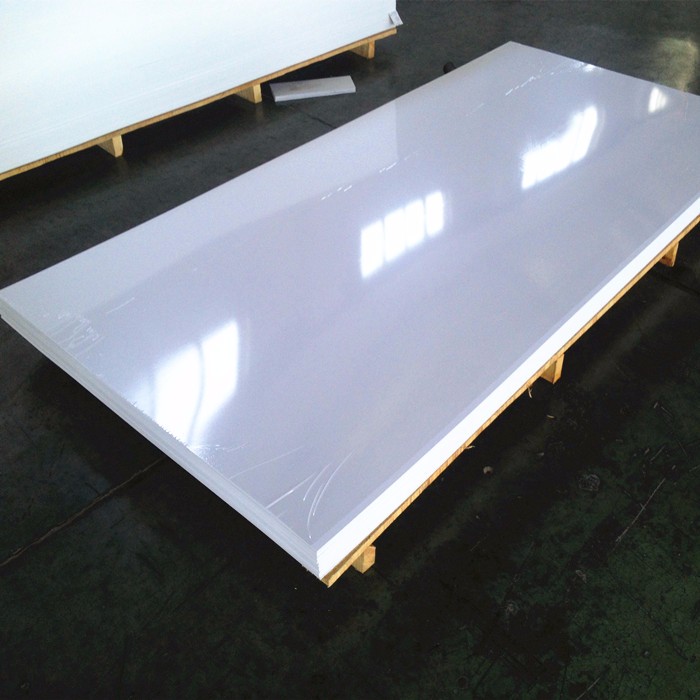

| Regular Size | 1220x2440mm, 2050x3050mm, 1560x3050mm |

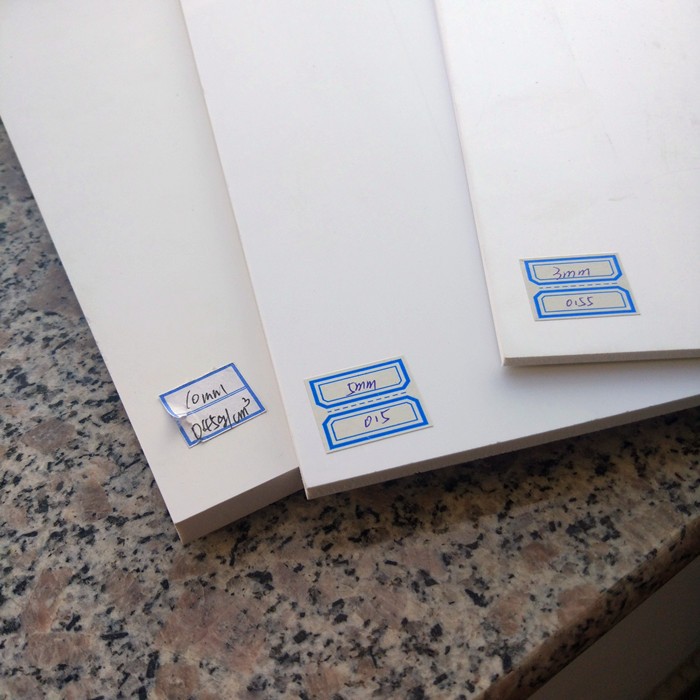

| Thickness | 1mm~30mm |

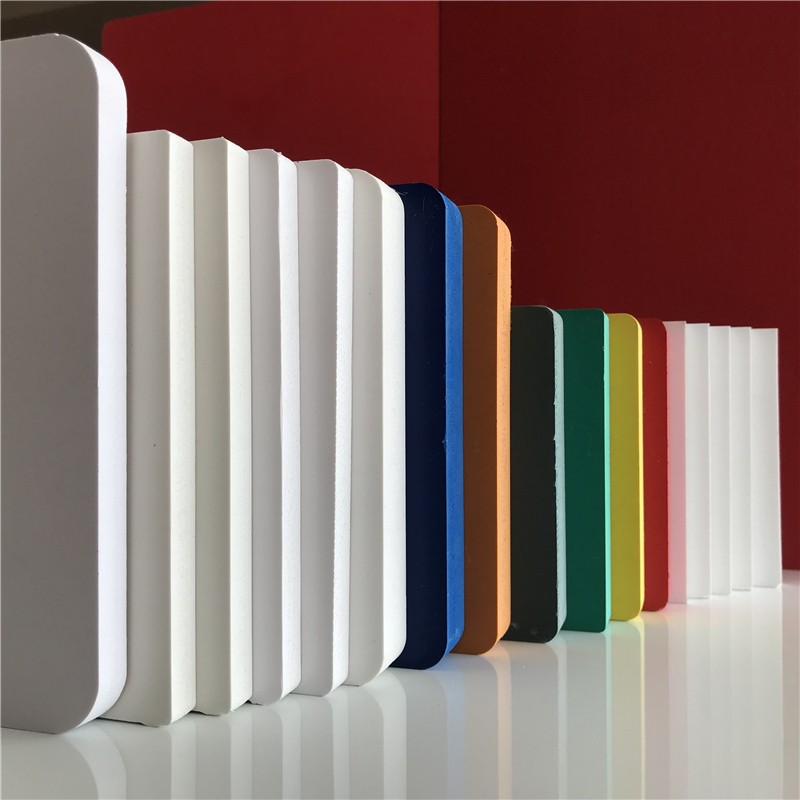

| Color | White, Black, Others, such as red, yellow, blue and green |

| Density | 0.3g/cm3~0.9g/cm3 |

| Type | PVC Free Foam 1mm ~ 4mm PVC Celuka Foam 5mm ~30mm |

| HS code | 3921129000 |

We are specialized in manufacturing PVC foam board.There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise.And now we have 20 production line for PVC foam board.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

PVC Foaming Board Not only has all the advantages of wood, but also have many characteristics that general wood does not have , can be a comprehensive replacement of wood, plywood, Polaroid board, particleboard, medium density plate and other plates.

PVC foam board, thickness 1-4mm, ca 20%, screen printing applications require free foaming sheet.

PVC Celuka Board, ca 31%, thickness more than 2mm

PVC RIGID Board, ca 5%, surface hardness is the highest, printing is generally used free foaming, some UV printing to do co-extrusion can also be.

lead free PVC SINTRA

Feature of PVC

1. Light weight

2. Stable color retention

3. Outstanding print ability

4. Easily cleaning

5. Waterproofing. Moisture proof.Dampproof.

6. Fire resistant and self-extinguishing.

7. Heat preservation.

8. Sound-insulated. Heat insulating

9. Non-corrosion.

10. Non-toxic.

11. Tough, rigid with the high impact strength.

12. Anti - deformed

Advantage:

30years experience to manufacture

Excellent quality and good price

Manufacture according to customer’s requirement

Application:

a. Advertising, Digital Print, Carve Letters silk screen printing, engraving materials, exhibition board flat solvent printing, billboard and exhibition display.etc.

b. Cabinets, Bathroom Cabinet, Kitchen Cabinet, Furniture etc.

c. Decoration, Display Board decorative sheets outdoors and indoors, storage racks, etc.

d. 1mm, 1.5mm Thickness PVC Foam Sheets, Use as Album, Menu Book Inside Page Material etc.

e. Vessel Vehicle: interior decorating materials of buses, train, subway,

f. Industrial Application:thermoformed products, refrigeratory warehouse project

g. Building outdoor wall board, indoor decoration board, partition board in office and house.

h. Chemical anti corrosion project, special cold project, environmental protection

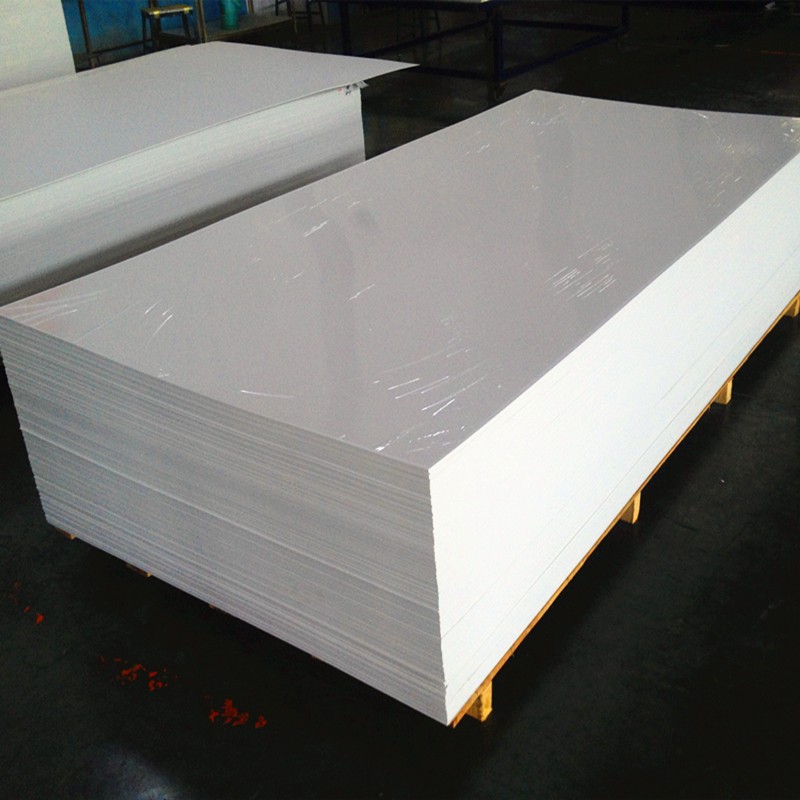

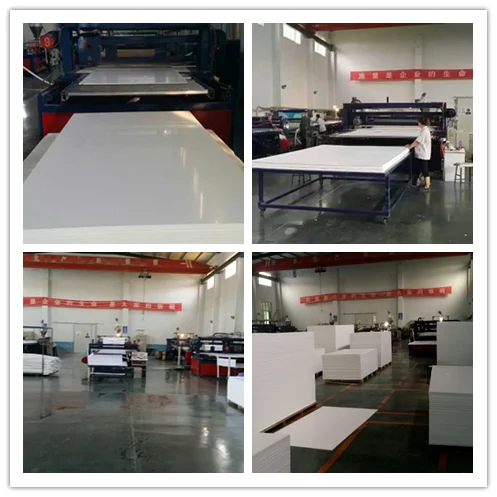

Workshop and production lines (there are 20 production lines for PVC in our factory)

Warehouse

Packed in PE bag (5-10 pcs per PE bag)

Ready for delivery

Loading to truck

Reinforce after packing