3mm Acrylic PMMA Plexiglass Diffuser Sheet Panel Plate Led Light

Brand : ALANDS

Product origin : Jinan,China

Delivery time : 10-15 days

Supply capacity : 500 Ton/Tons per Month

3mm Acrylic PMMA Plexiglass Diffuser Sheet Panel Plate Led Light

3mm Acrylic PMMA Plexiglass Diffuser Sheet Panel Plate Led Light

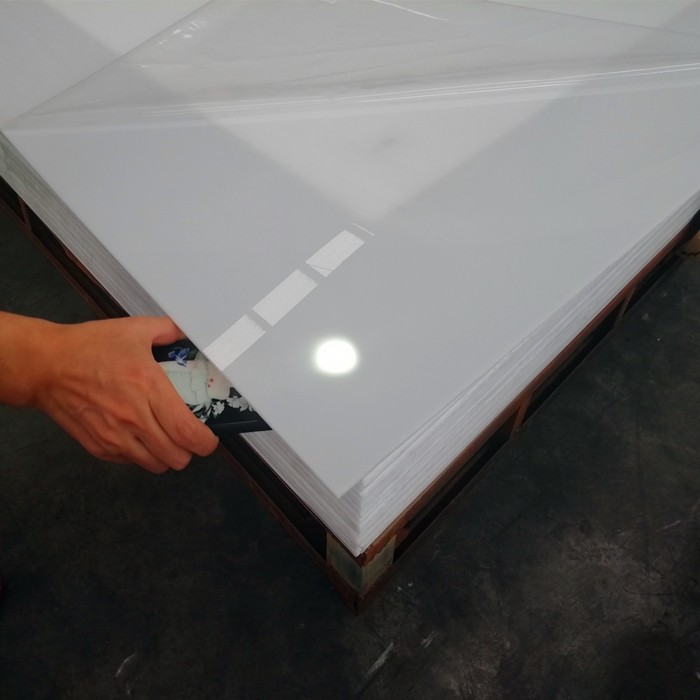

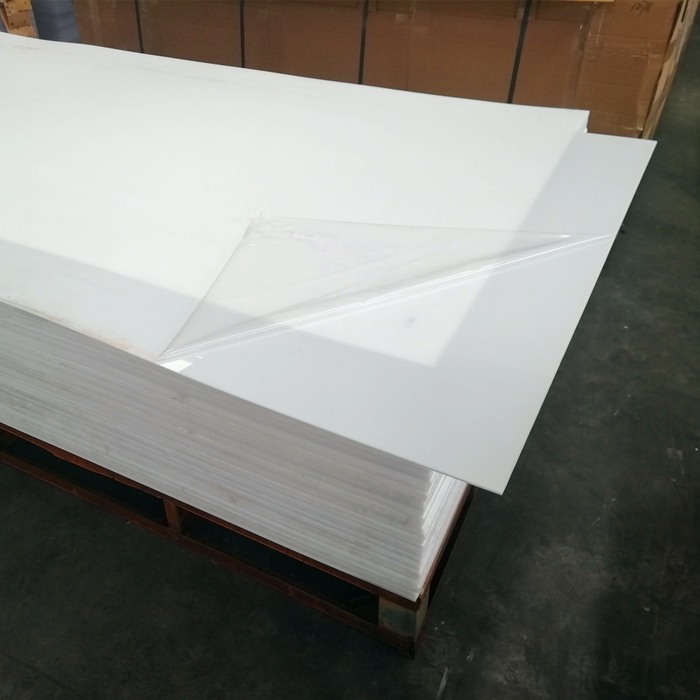

100% virgin clear acrylic sheet 1220*2440

Alands 3mm Acrylic PMMA Plexiglass Diffuser Sheet

Panel Plate Led Light

Product Name | 3mm Acrylic PMMA Plexiglass Diffuser Sheet Panel Plate Led Light |

Material | 100% Virgin MMA, high quality MMA raw material |

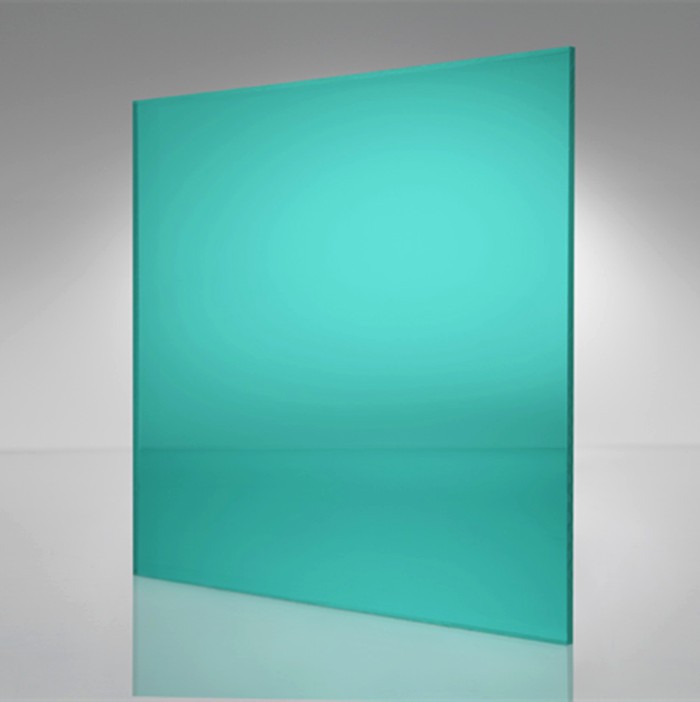

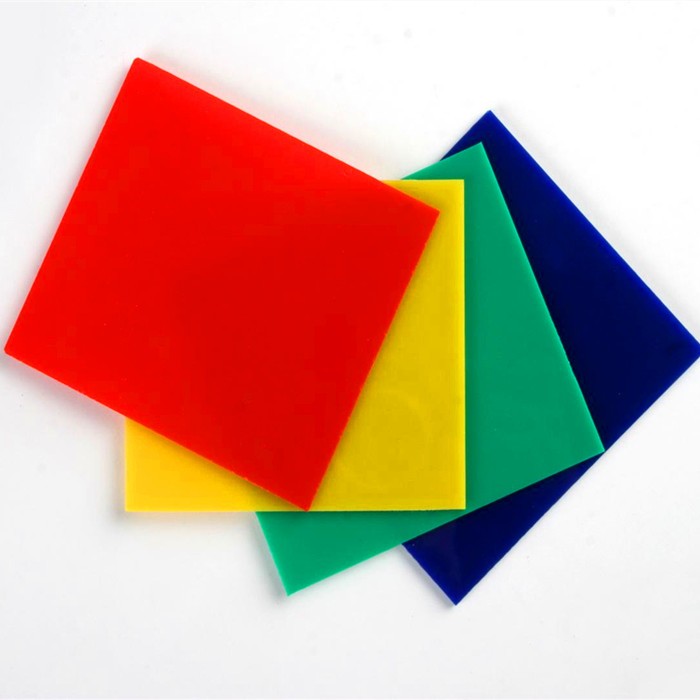

Color | Milky white, black, transparent.etc, any colors can be customized |

Thickness | 2mm to 30mm |

Size (mm) | 1020*2020 1250*1850 1250*2450 1850*2450 1530*2130 1600*2600 2050*3050 |

Technical Properties

Specific Gravity | 1.2g/cm3 | Light Transmittance | 93% |

Shear Strength | 630Kg/cm2 | Rockwell Hardness | M-100 |

Tensile Strength | 760Kg/cm2 | Refractive Index | 1.49 |

Yield Strength | 1260Kg/cm2 | Heat Distortion Temperature | 100℃ |

Rupture Strength | 1050Kg/cm2 | Thermal Forming Temperature | 140-180℃ |

Dielectric Strength | 20Kv/mm | Absorptivity of water (24h) | 0.3% |

100% virgin clear acrylic sheet 1220*2440

100% virgin clear acrylic sheet 1220*244

1. light box 2. outdoor sign board 3. Signage board

4. advertising material 5. decoration material 6. display shelf

7. daily product 8. furniture 9. noise wall

10. skylight 11. train and car windows 12. handicraft product

13. food packing 14. acrylic aquarium 15. bathroom product

Excellent transparency (for clear or transparent sheet).

Good mechanical performance and Good electrical insulation.

Stable and durable.

Non-toxic, environmental friendly.

Superior impact resistance. Crack resistance.

Superior weather resistance.

UV light resistance.

Chemical resistance.

Stable color under outdoor exposure.Suitable for laser engraving, CNC cutting and vacuum forming

1.What's the difference between cast and extruded acrylic?

Acrylic is produced in two basic ways, cast and extruded. Cast acrylic is produced by mixing the acrylic liquid ingredients in mould. A chemical process in the mould creates a homogeneous material with equivalent properties in all directions. In contrast, extruded acrylic is produced by continuously pushing acrylic mass through a form, while the chemical process takes place.

Extruded acrylic is therefore heterogeneous, with properties which vary depending on the direction. We call it the extrusion direction for acrylic sheets.

Laser cutting

When laser cutting extruded acrylic , there will become blurry on one side. On the cast acrylic there is not the case. The edges on extruded acrylic may look a bit different depending on the direction of the acrylic extrusion.

Laser engraving

The Laser engraving will on extruded acrylic look matte Grey. On the cast acrylic will look matte white.

Heat bending and Thermoforming

A sheet of extruded acrylic could, because of the acrylic extrusion direction, behave differently depending on the bending direction relatively to the extrusion. With cast acrylic, it makes no difference.

When cast colour acrylic is heated for Thermoforming or heat bending the colour can change. Matte side can become clear and clear side can become matte. In addition, the shade of color can change. Cast acrylic is harder to bend / shape.

Scratch-resistant

Cast acrylic is more scratch resistant than extruded acrylic.

Flame polishing

Cast acrylic is harder to flame polish.

Colour

Cast acrylic is produced in many different colors and thicknesses. The colour selection is limited for extruded acrylic.

Tension

There is more tension in extruded acrylic.

2.Does acrylic discolour if left in the sun?

Most of the acrylic sheets sold by Alands are UV Stabilized otherwise stated as indoor use only (eg: acrylic mirror sheets). This means that with proper maintenance of the acrylic sheet, it should last 10 years or more before it ever yellows.

3.Is acrylic food safe?

Please be advised that clear cast acrylic sheets are in compliance with the FDA Food Additive Regulation 21CFR177.1010 ( Acrylic and Modified Acrylic Plastics, Semi-Rigid and Rigid ) for use in contact with all types of food except for high alcohol content foods (greater than 8% alcohol) at or below room temperature.

4.What is the best way to clean acrylic?

Acrylic sheeting can be damaged by harsh solvents and cleaners. Use a commercial plastic cleaner or mild soap and water to remove dirt and debris. When applying cleaner, use a non-abrasive lint-free or microfiber cloth that won’t scratch the surface. For tough grease, oil, or tar residue, use commercial grade hexane or kerosene. All solvents need to be wiped clean with fresh water and blotted dry to reduce and prevent water spotting.

When cleaning acrylic sheeting, never use ammonia, acetone, carbon tetra-chloride, or gasoline as a cleaning solution. These kinds of solvents can cause cracks in acrylic sheeting and give the surface a frosted appearance.

5. What about your quality guarantee for acrylic sheet?

1) The weight and thickness of each sheet is enough;

2) The surface is smooth, no scratch, no bubbles or spot on the whole sheet;

3) Clear sheet transparency reach to 93%, won't change yellow in 6-8 years;

4) Every acrylic sheets must be tested strictly to ensure no flaws before shipping;

5) If any quality problem, we promise refund the all your payment.